Maximizing Equipment Performance with AI-Driven Predictive Maintenance Services

Maintenance teams traditionally struggle to prevent equipment failures, often reacting to issues after costly breakdowns occur.

The challenge of anticipating equipment issues before they happen has led to inefficiencies, increased downtime, and higher operational costs.

The advent of AI and machine learning has transformed this scenario through advanced predictive maintenance services. These services proactively identify potential issues by continuously monitoring equipment and analyzing data in real-time, thereby optimizing maintenance schedules and significantly reducing downtime.

Key Takeaways

Advance towards smarter maintenance solutions.

Fill in your company’s information and assess how AI predictive maintenance can drive cost savings and efficiency.

AI predictive maintenance services utilize machine learning, data analytics, and IoT (Internet of Things) technologies to anticipate equipment failures before they occur, thereby reducing downtime, extending equipment life, and optimizing maintenance schedules. By analyzing data from sensors, logs, and historical maintenance records, AI models can identify patterns and predict potential breakdowns, allowing for proactive maintenance actions. Here’s how you can explore the integration of AI predictive maintenance services to enhance equipment efficiency in your operations:

### Customizable Prompt for Integrating AI Predictive Maintenance Services

"How can [Company Name], operating within the [Industry], implement AI predictive maintenance services to optimize equipment efficiency, reduce operational downtime, and achieve cost savings? Consider the use of machine learning algorithms, real-time data monitoring, and predictive analytics to anticipate and address maintenance needs."

#### Areas to Explore:

1. **Data Collection and Analysis**: How can [Company Name] set up a comprehensive system for collecting and analyzing data from its equipment using sensors and IoT devices? Explore the types of data that are most critical for predictive maintenance in [Industry].

2. **Machine Learning Model Development**: Discuss the process of developing and training machine learning models to identify patterns and predict potential equipment failures. Consider the integration of historical maintenance records and real-time data.

3. **Real-Time Monitoring and Alerts**: How can [Company Name] implement a real-time monitoring system that uses AI to provide alerts for potential equipment issues before they lead to failure?

4. **Maintenance Scheduling Optimization**: Explore ways in which AI predictive maintenance can help [Company Name] optimize its maintenance schedules, ensuring that equipment is maintained just in time to prevent breakdowns without unnecessary downtime.

5. **ROI and Cost-Benefit Analysis**: Discuss how [Company Name] can conduct a cost-benefit analysis to understand the ROI of implementing AI predictive maintenance services, considering factors like reduction in downtime, maintenance costs, and equipment lifespan extension.

6. **Integration with Existing Systems**: How can [Company Name] ensure the seamless integration of AI predictive maintenance services with its existing operational and IT systems? Consider the challenges and strategies for integration.

### Guide for Use:

- Personalize the prompt with details specific to your company, including the industry you operate in and the types of equipment used in your operations.

- Use the insights generated to identify potential benefits, challenges, and implementation strategies for AI predictive maintenance in your context.

- Consider partnering with AI solutions providers or investing in in-house AI expertise to develop and implement predictive maintenance capabilities.

- Evaluate the effectiveness of the AI predictive maintenance system regularly and make adjustments as needed to continually improve performance and ROI.

Integrating AI predictive maintenance into your operations can significantly enhance equipment efficiency, reduce downtime, and contribute to substantial cost savings, thereby supporting overall operational excellence and competitiveness.The Role of AI Predictive Maintenance Services

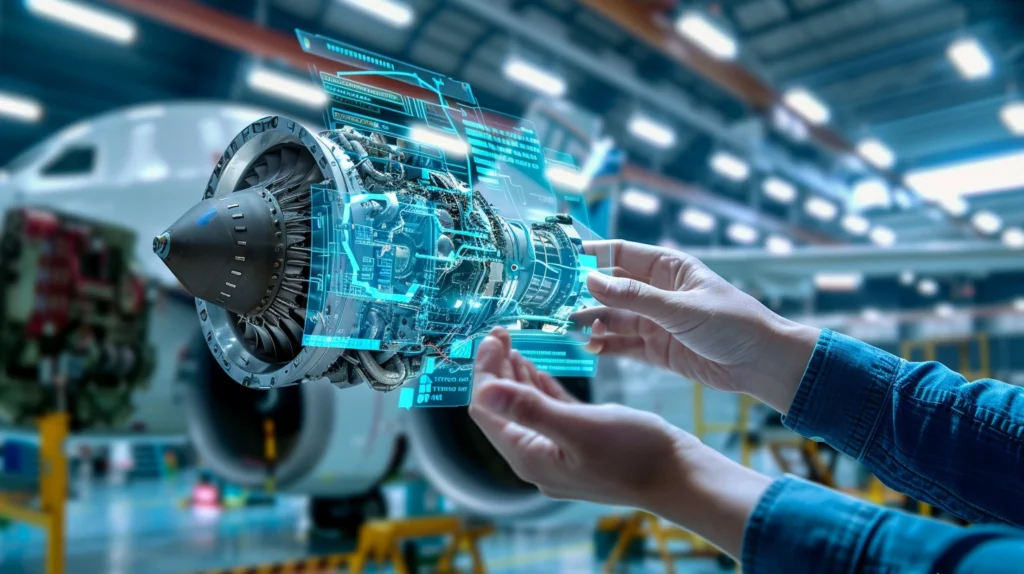

When it comes to predictive maintenance, AI plays a crucial role in ensuring the smooth operation of equipment and minimizing downtime. By harnessing the power of artificial intelligence, maintenance teams can proactively identify potential machine failures before they happen, preventing costly disruptions and optimizing maintenance activities.

AI-driven predictive maintenance software analyzes real-time data collected from sensors and IoT devices. Through advanced machine learning algorithms, AI can detect patterns and anomalies that may indicate impending equipment failures. This real-time monitoring and analysis allow maintenance teams to take proactive measures to rectify issues, preventing unplanned downtime and the resulting adverse effects on productivity and profitability.

With AI in predictive maintenance, the focus shifts from reactive repairs to proactive and preventative strategies. By leveraging AI-driven insights, maintenance teams can establish optimized maintenance schedules and allocate resources effectively. This approach helps prevent equipment failures and extends the lifespan of critical assets, resulting in increased operational efficiency and reduced costs.

By incorporating AI technology into predictive maintenance, companies can transform their maintenance operations and streamline their processes. With continuous monitoring and analysis of data, AI-driven systems can deliver actionable recommendations that further enhance the overall maintenance strategy and decision-making process. This integration of AI and predictive maintenance not only helps prevent equipment failures but also ensures optimal equipment performance, reducing maintenance costs, and maximizing productivity.

To fully grasp the impact of AI in predictive maintenance, let’s consider an example. Imagine a manufacturing plant that relies heavily on a specific machine for its production. Without AI, maintenance teams would follow a reactive approach, only fixing issues after the machine breaks down, leading to unplanned downtime and reduced productivity. However, with AI-driven predictive maintenance, the machine’s real-time data can be continuously monitored and analyzed, allowing maintenance teams to anticipate potential failures and schedule maintenance activities preemptively. This proactive approach ultimately prevents equipment failures and significantly reduces unplanned downtime, ensuring uninterrupted production and minimizing financial losses for the company.

As the image above illustrates, AI in predictive maintenance has a transformative potential, revolutionizing maintenance operations across various industries. By harnessing the power of AI technology to prevent equipment failures and optimize maintenance activities, companies can gain a competitive edge, reduce costs, and maintain operational efficiency in today’s fast-paced and demanding business landscape.

The Importance of Predictive Maintenance in Various Industries

Predictive maintenance plays a vital role in ensuring asset reliability and preventing costly failures across various industries. In the manufacturing industry, early fault detection and diagnosis are of utmost importance to maintain asset reliability and prevent disruptions in operations. By implementing AI-driven predictive maintenance solutions, companies can effectively predict potential issues, anticipate failures, and take preventive actions to mitigate risks.

Leading manufacturing companies rely on AI technology to continuously monitor equipment performance, collect real-time data, and analyze patterns to identify potential failures before they occur. This proactive approach improves equipment effectiveness, reduces unplanned downtime, and ensures the smooth operation of manufacturing processes.

“Predictive maintenance is the key to maintaining asset reliability and preventing costly failures in the manufacturing industry.”

Service technicians also benefit greatly from predictive maintenance. By leveraging AI technology, service technicians can proactively prepare for maintenance activities and stay ahead of potential issues. They can utilize data-driven insights to plan maintenance schedules, allocate resources efficiently, and minimize disruptions to operations.

| Benefits of Predictive Maintenance in Various Industries: |

|---|

| Improved asset reliability |

| Reduced unplanned downtime |

| Optimized maintenance schedules |

| Cost savings from preventing major equipment failures |

| Efficient resource allocation |

The Integration of AI in Maintenance Operations

The integration of AI in maintenance operations is revolutionizing the way organizations conduct their maintenance activities. By harnessing the power of advanced analytics and AI algorithms, maintenance teams can analyze vast amounts of data to gain predictive insights and optimize maintenance schedules. This enables organizations to reduce costs, improve asset reliability, and ensure optimal equipment performance through strategic and focused scheduled maintenance.

In today’s data-driven world, the ability to extract actionable insights from complex data sets is critical. AI, with its advanced analytics capabilities, can continuously monitor critical assets, assess asset performance, and predict maintenance needs. By leveraging AI technologies, organizations can proactively identify potential issues before they escalate into costly equipment failures, allowing for timely corrective actions.

The benefits of integrating AI in maintenance operations are numerous. The use of advanced analytics enables maintenance teams to identify patterns and anomalies in asset performance, empowering them to make data-driven decisions and take preventive measures. By optimizing maintenance schedules based on real-time data and predictive analytics, organizations can minimize downtime, reduce maintenance costs, and improve overall asset reliability.

“The integration of AI in maintenance operations has transformed our approach to maintenance. With advanced analytics and predictive insights, we have been able to proactively address maintenance needs, significantly reducing downtime and improving asset performance.”

Improving Maintenance Strategies with AI

By integrating AI into maintenance operations, organizations can shift from reactive to proactive maintenance strategies. The ability to predict maintenance needs allows maintenance teams to plan and schedule activities more efficiently, ensuring that critical assets receive the attention they require.

AI-driven maintenance also enables organizations to optimize the allocation of resources. By focusing on critical assets, maintenance teams can prioritize their efforts and allocate resources strategically, reducing costs and maximizing the impact of maintenance activities.

In addition, AI integration provides a better understanding of asset performance, allowing organizations to identify underlying issues and implement targeted corrective actions. This proactive approach minimizes the risk of equipment failures, improves overall asset performance, and enhances operational efficiency.

The Role of Advanced Analytics in Maintenance

Advanced analytics is a cornerstone in the integration of AI in maintenance operations. By leveraging powerful algorithms, maintenance teams can analyze complex data sets to extract valuable insights about asset performance and maintenance needs. This data-driven approach facilitates evidence-based decision-making and supports the optimization of maintenance strategies.

With the help of AI algorithms and advanced analytics, maintenance teams can:

- Predict equipment failures and proactively address maintenance needs

- Identify the impact of asset performance on overall operations

- Optimize maintenance schedules based on real-time data

- Allocate resources strategically to critical assets

- Improve overall asset reliability and minimize downtime

By harnessing the power of advanced analytics, organizations can unlock the full potential of their maintenance operations and pave the way for a more proactive, efficient, and reliable maintenance approach.

| Benefits of AI Integration in Maintenance Operations | Key Advantages |

|---|---|

| Improved asset performance | By continuously monitoring critical assets, AI can detect performance issues and help maintenance teams address them promptly. |

| Optimized maintenance schedules | AI algorithms analyze data to predict maintenance needs, allowing organizations to plan and schedule maintenance activities more efficiently. |

| Reduced downtime and costs | Proactive maintenance based on AI insights minimizes the risk of equipment failures, reducing costly unplanned downtime and maintenance expenses. |

| Enhanced asset reliability | By identifying potential issues before they escalate into failures, AI integration improves overall asset reliability and extends the lifespan of critical assets. |

Automation in Maintenance Operations

Automation plays a crucial role in maintenance operations, particularly in the context of AI-driven predictive maintenance. By utilizing machine learning algorithms and predictive analytics, maintenance teams can automate data collection and analysis, enabling real-time monitoring of equipment performance.

Through continuous analysis of data and identification of patterns, maintenance teams can anticipate potential equipment failures and take proactive actions. This automation not only helps reduce downtime but also improves the efficiency of maintenance activities, providing meaningful insights for better decision-making.

AI-driven predictive maintenance solutions empower maintenance teams to address issues at their earliest stages, minimizing equipment downtime, and maximizing overall efficiency.

Machine Learning Algorithms and Predictive Analytics

The integration of machine learning algorithms and predictive analytics forms the foundation of automation in maintenance operations. These technologies allow predictive maintenance systems to analyze vast amounts of data and make accurate predictions regarding potential equipment failures.

Machine learning algorithms use historical data to recognize patterns and anomalies, which helps maintenance teams identify equipment malfunctions before they occur. This predictive capability enables proactive maintenance activities and reduces the likelihood of unexpected breakdowns.

Predictive analytics, on the other hand, provide maintenance teams with valuable insights derived from data analysis. By leveraging these insights, teams can make informed decisions regarding maintenance scheduling, resource allocation, and equipment optimization.

Reducing Downtime through Automation

Reducing equipment downtime is a critical goal of maintenance operations, and automation plays a key role in achieving this objective. By continuously monitoring equipment performance and analyzing data in real-time, maintenance teams can identify potential issues before they lead to breakdowns.

This proactive approach allows teams to plan maintenance activities strategically, ensuring that maintenance activities are carried out at optimal times. By addressing issues early on, maintenance teams can minimize downtime and maintain the smooth operation of equipment and systems.

In addition to reducing downtime, automation in maintenance operations also helps improve the efficiency of maintenance activities. By automating data collection and analysis, maintenance teams can streamline their workflows and focus on high-priority tasks, resulting in more efficient maintenance operations.

Improved Decision-Making through Meaningful Insights

Automation in maintenance operations provides maintenance teams with meaningful insights derived from data analysis. These insights empower teams to make informed decisions regarding maintenance activities, resource allocation, and equipment optimization.

By leveraging the power of machine learning algorithms and predictive analytics, maintenance teams gain a deeper understanding of equipment performance and potential failure patterns. This understanding enables them to prioritize maintenance activities effectively and allocate resources where they are most needed, thereby optimizing maintenance operations.

“By automating the data collection and analysis process, maintenance teams can focus on proactive maintenance activities rather than reactive ones. This shift in approach helps reduce downtime, increase equipment reliability, and enhance overall operational efficiency.”

| Maintenance Activities | Benefits |

|---|---|

| Real-time monitoring of equipment performance | Identifying potential issues before they lead to breakdowns |

| Proactive maintenance scheduling | Reducing equipment downtime |

| Streamlined workflows | Improving maintenance efficiency |

| Data-driven decision-making | Optimizing resource allocation and equipment optimization |

AI-Driven Predictive Maintenance Solutions

AI-driven predictive maintenance solutions revolutionize traditional maintenance practices by harnessing the power of AI technology. These innovative solutions optimize maintenance schedules based on real-time data and predictive analytics, ensuring efficient and proactive maintenance operations.

To enable predictive maintenance, AI-driven solutions collect data from various sources, including sensors and IoT devices. This data provides a comprehensive view of equipment performance and allows maintenance teams to monitor critical assets closely.

The data collected is then analyzed using advanced AI algorithms, which detect anomalies, patterns, and potential signs of equipment failure. This deep analysis enables maintenance teams to take timely corrective actions, preventing catastrophic asset failures and extending the lifespan of critical assets.

The insights generated by AI-driven predictive maintenance solutions also help optimize maintenance schedules. By predicting potential equipment failures, maintenance teams can proactively allocate resources, plan maintenance activities, and avoid unplanned downtime, leading to significant cost savings and improved operational efficiency.

Additionally, these solutions provide valuable recommendations for maintenance teams, enabling them to make data-driven decisions and prioritize maintenance tasks effectively. By leveraging the power of AI, maintenance teams can enhance their overall maintenance operations, ensure asset reliability, and mitigate the risk of unexpected equipment failures.

Benefits of AI-Driven Predictive Maintenance Solutions:

- Optimized maintenance schedules based on real-time data analysis

- Timely detection of anomalies and potential signs of equipment failure

- Prevention of asset failures and extension of asset lifespan

- Improved resource allocation and planning of maintenance activities

- Cost savings through reduced unplanned downtime

- Enhanced operational efficiency and asset reliability

- Data-driven decision-making and prioritization of maintenance tasks

Overall, AI-driven predictive maintenance solutions empower maintenance teams with valuable insights, actionable recommendations, and proactive strategies to effectively manage assets and optimize maintenance operations.

| Benefits | Description |

|---|---|

| Optimized maintenance schedules | Proactive planning and resource allocation based on real-time data analysis |

| Timely detection of issues | Identification of anomalies and potential signs of equipment failure to enable prompt corrective actions |

| Prevention of asset failures | Proactive measures to prevent catastrophic asset failures and extend asset lifespan |

| Improved resource allocation | Efficient allocation of resources and effective planning of maintenance activities |

| Cost savings | Reduction in unplanned downtime and associated costs |

| Enhanced operational efficiency | Improved asset reliability and overall operational efficiency |

| Data-driven decision-making | Utilization of insights and recommendations to make informed decisions |

The Impact of AI in Predictive Maintenance Across Industries

The impact of AI in predictive maintenance is significant across various industries. AI applications play a crucial role in optimizing maintenance activities, increasing productivity, and improving product quality in manufacturing operations. By leveraging AI-driven predictive maintenance, service leaders can anticipate failures, reduce unplanned downtime, and allocate resources efficiently.

AI algorithms analyze data collected from sensors and IoT devices to gain insights into equipment performance. This data-driven approach enables maintenance teams to determine the root cause of failures and implement preventive maintenance measures. By staying ahead of potential issues, industries can enhance overall operational efficiency and minimize disruptions.

Enhancing Manufacturing Operations

In manufacturing operations, AI applications revolutionize maintenance activities, leading to improved equipment effectiveness and reduced downtime. By continuously analyzing real-time data, AI algorithms identify patterns and anomalies that indicate potential failures. This enables maintenance teams to take preventive actions, optimizing maintenance schedules and minimizing disruptions.

Moreover, AI-driven predictive maintenance solutions empower manufacturing operations to increase productivity and improve product quality. By proactively addressing equipment issues, companies can ensure smooth operations, reduce costly downtime, and deliver high-quality products to customers.

Empowering Service Leaders

Service leaders across industries benefit from AI-driven predictive maintenance solutions. By leveraging AI technology, they can accurately anticipate failures and allocate resources efficiently. With the ability to analyze data and apply AI algorithms, service leaders gain a better understanding of equipment performance and can take proactive measures to prevent disruptions.

“AI in predictive maintenance enables service leaders to stay ahead of potential issues and make data-driven decisions that enhance operational efficiency.”

By proactively managing maintenance activities, service leaders can reduce unplanned downtime, optimize resource allocation, and provide better service to their customers.

Implementing Preventive Maintenance Measures

AI in predictive maintenance enables industries to implement preventive maintenance measures effectively. By analyzing data collected from sensors and IoT devices, AI algorithms can detect anomalies and predict potential equipment failures. This allows maintenance teams to determine the root cause of failures and implement timely corrective actions.

Preventive maintenance measures help industries avoid costly breakdowns, optimize equipment performance, and extend the lifespan of critical assets. By leveraging AI technology, industries can proactively address maintenance needs, minimizing disruptions and ensuring smooth operations.

| Industry | Benefits of AI in Predictive Maintenance |

|---|---|

| Manufacturing | – Optimized maintenance activities – Increased equipment effectiveness – Improved product quality – Reduced downtime |

| Service Industry | – Anticipated failures – Efficient resource allocation – Minimized unplanned downtime – Enhanced customer satisfaction |

| All Industries | – Preventive maintenance implementation – Timely corrective actions – Minimized disruptions – Extended asset lifespan |

Real-World Implementations of AI in Predictive Maintenance

Real-world implementations of AI in predictive maintenance demonstrate its effectiveness in optimizing maintenance operations. By integrating IoT technology, maintenance teams can collect vast amounts of data from equipment, which is then processed by AI algorithms. This integration enables real-time monitoring of equipment performance, empowering teams to identify potential issues and proactively address them.

AI-driven predictive maintenance plays a crucial role in determining the root cause of failures, allowing for effective and targeted corrective actions. By analyzing the data collected, AI algorithms can identify patterns and anomalies, providing maintenance teams with valuable insights to prevent equipment failures and minimize downtime.

In the next generation of maintenance operations, AI will continue to be a key driver in preventing equipment failures, reducing downtime, and maximizing overall efficiency. With continuous advancements in AI technology, maintenance teams can leverage predictive maintenance solutions to optimize maintenance activities and improve equipment reliability.

Image:

Real-World Examples of AI in Predictive Maintenance

| Industry | Implementation |

|---|---|

| Manufacturing | Leading manufacturing companies have integrated IoT devices with AI-driven predictive maintenance to monitor equipment performance in real-time. By analyzing data from sensors, they can identify potential issues and schedule preventive maintenance, reducing downtime and maximizing production efficiency. |

| Energy | Energy companies are utilizing AI algorithms to analyze data collected from power generation equipment. By predicting maintenance needs and addressing potential failures proactively, they can optimize asset performance and extend the lifespan of critical equipment. |

| Transportation | In the transportation industry, AI-powered predictive maintenance solutions enable maintenance teams to monitor the condition of vehicles and perform timely maintenance. This helps prevent breakdowns, improve safety, and optimize the lifespan of vehicles. |

These real-world implementations highlight how AI integration in predictive maintenance revolutionizes maintenance operations across various industries. By harnessing the power of AI, companies can enhance equipment performance, reduce maintenance costs, and ensure uninterrupted operation of critical assets.

The Future of Predictive Maintenance with AI

As technology continues to advance, the future of predictive maintenance lies in the widespread adoption and integration of AI (Artificial Intelligence). With AI algorithms evolving at a rapid pace, maintenance teams can expect more accurate predictions and actionable insights to enhance their operations.

One key aspect of the future of AI-driven predictive maintenance is the implementation of regular intervals of data collection and analysis. By making this practice a standard procedure, maintenance teams can effectively identify potential issues before they escalate into costly equipment failures. This proactive approach mitigates downtime and ensures the smooth operation of critical assets across industries.

In addition, AI will have broader applications within predictive maintenance, benefiting various sectors and domains. From manufacturing and service industries to energy and healthcare, AI adoption enables organizations to gain a better understanding of equipment performance and anticipate maintenance needs more effectively.

The integration of AI and predictive maintenance promises improved efficiency and productivity in maintenance activities. By harnessing the power of AI, companies can optimize their maintenance schedules, streamline operations, and maximize the lifespan and reliability of critical assets. As AI continues to advance and mature, the future of predictive maintenance looks promising, offering industries the potential for better insights, reduced costs, and enhanced operational performance.

Starting a Side Hustle in AI Predictive Maintenance

Are you looking for a profitable side hustle that leverages the power of Artificial Intelligence (AI)? Consider starting a business in AI predictive maintenance. According to a report by MarketsandMarkets, the AI predictive maintenance market is projected to grow from USD 3.8 billion in 2020 to USD 11.1 billion by 2025, at a CAGR of 23.2% during the forecast period. (Source: MarketsandMarkets)

What is AI Predictive Maintenance?

AI predictive maintenance is a proactive approach to equipment maintenance using AI and machine learning algorithms to analyze data from sensors and identify potential issues before they cause downtime or significant damage.

Why Start a Side Hustle in AI Predictive Maintenance?

- High Demand: With the increasing use of machinery and equipment in various industries, the need for predictive maintenance solutions is on the rise.

- Profitability: Predictive maintenance can help businesses save on maintenance costs, reduce downtime, and increase productivity.

- Flexibility: A side hustle in AI predictive maintenance can be started with minimal investment and can be run remotely.

Steps to Starting Your Side Hustle

- Learn the Basics: Familiarize yourself with AI, machine learning, and predictive maintenance concepts. There are various online courses and resources available to help you get started.

- Identify Your Niche: Decide which industry or type of equipment you want to focus on.

- Build Your Team: If you don’t have the necessary expertise in-house, consider partnering with other professionals or outsourcing certain tasks.

- Invest in Tools: Look for AI predictive maintenance software and tools that can help you analyze data and provide insights to your clients.

- Market Your Services: Build a website, create social media profiles, and network with potential clients to promote your services.

Key Considerations

- Data Security: Ensure that you have robust data security measures in place to protect your clients’ data.

- Regulations: Familiarize yourself with any relevant regulations and certifications in your industry.

- Customer Service: Provide excellent customer service to build a strong reputation and retain clients.

Potential Challenges

- Data Quality: Ensure that the data you are analyzing is accurate and reliable.

- Competition: There may be other providers offering similar services, so differentiating yourself will be crucial.

- Scaling: As your business grows, you may need to invest in additional resources and infrastructure to keep up with demand.

Conclusion

Starting a side hustle in AI predictive maintenance can be a lucrative and rewarding opportunity. With the growing demand for predictive maintenance solutions and the flexibility of running a remote business, it’s an excellent choice for those looking to enter the tech industry. By following the steps outlined above and considering the key considerations, you can build a successful side hustle in this exciting field.

References:

- Teoh, Y. K., Gill, S. S., & Parlikad, A. K. (2021). IoT and fog-computing-based predictive maintenance model for effective asset management in Industry 4.0 using machine learning. IEEE Internet of Things Journal. https://ieeexplore.ieee.org/abstract/document/9319212/

- Çınar, Z. M., Nuhu, A. A., Zeeshan, Q., & Korhan, O. (2020). Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability. https://www.mdpi.com/2071-1050/12/19/8211

- Lee, W. J., Wu, H., Yun, H., Kim, H., Jun, M. B. G., & Sutherland, J. W. (2019). Predictive maintenance of machine tool systems using artificial intelligence techniques applied to machine condition data. Procedia CIRP. https://www.sciencedirect.com/science/article/pii/S2212827118312988

- Zhang, W., Yang, D., & Wang, H. (2019). Data-driven methods for predictive maintenance of industrial equipment: A survey. IEEE Systems Journal. https://ieeexplore.ieee.org/abstract/document/8707108/

- Zonta, T., Da Costa, C. A., Righi, R. D. R., & others. (2020). Predictive maintenance in the Industry 4.0: A systematic literature review. Computers & Industrial Engineering. https://www.sciencedirect.com/science/article/pii/S0360835220305787